TOOLS, JIGS & FIXTURE DESIGN

At Ceylon CAD, we specialize in the design and development of custom tools, jigs, and fixtures that enhance productivity, improve quality, and optimize manufacturing performance. Our designs are engineered to reduce setup time, minimize errors, increase repeatability, and support efficient production workflows.

With a strong mechanical engineering foundation and deep understanding of industrial processes, we provide practical and reliable fixture solutions that meet real-world fabrication and machining requirements. Whether you are manufacturing complex components, assembling equipment, or performing precision measurements, we can design systems that deliver accuracy, consistency, and long-term durability.

What We Offer

Welding Fixtures

- Customized fixtures designed to hold components in exact positions during welding to prevent distortion, ensure alignment, and maintain dimensional accuracy.

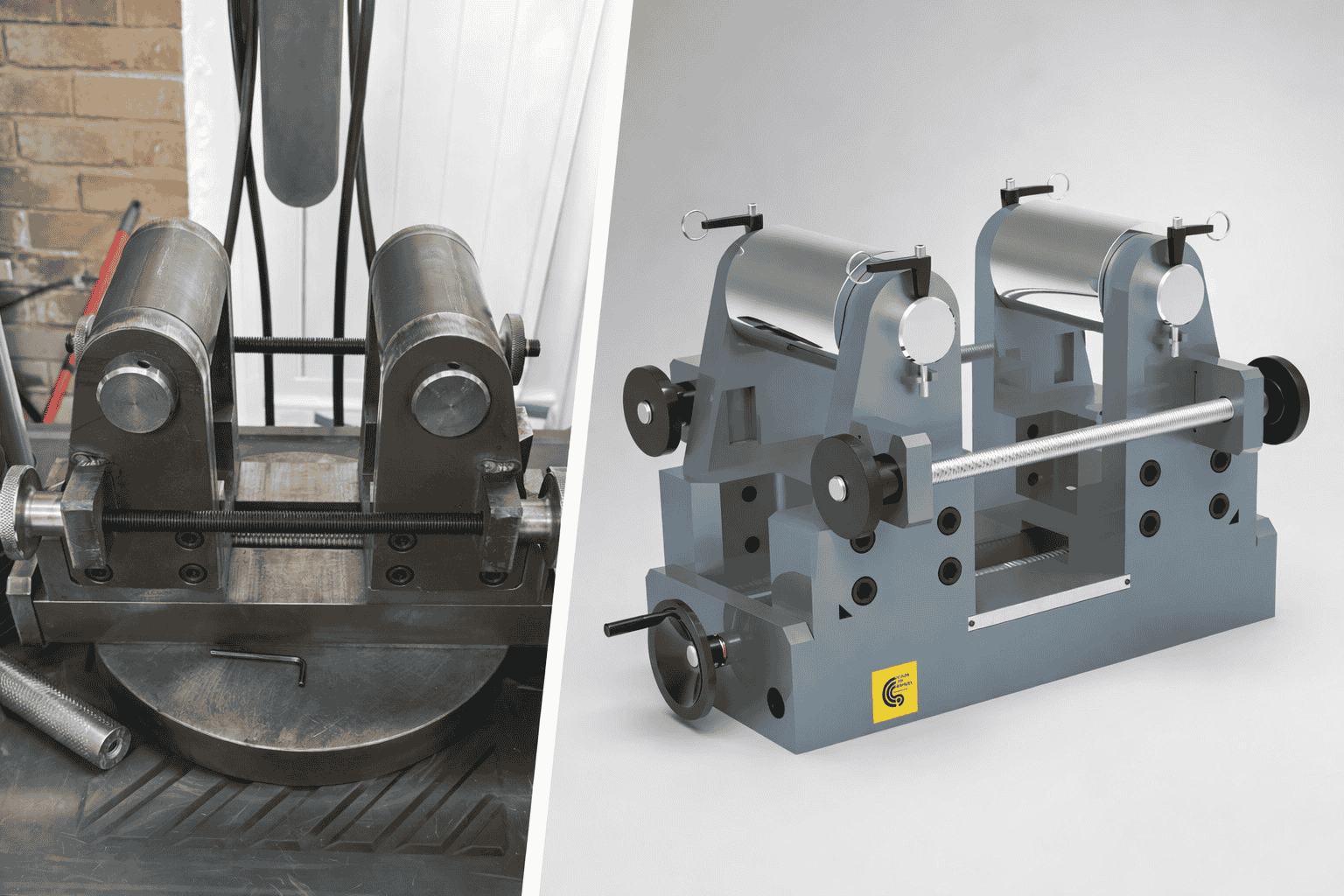

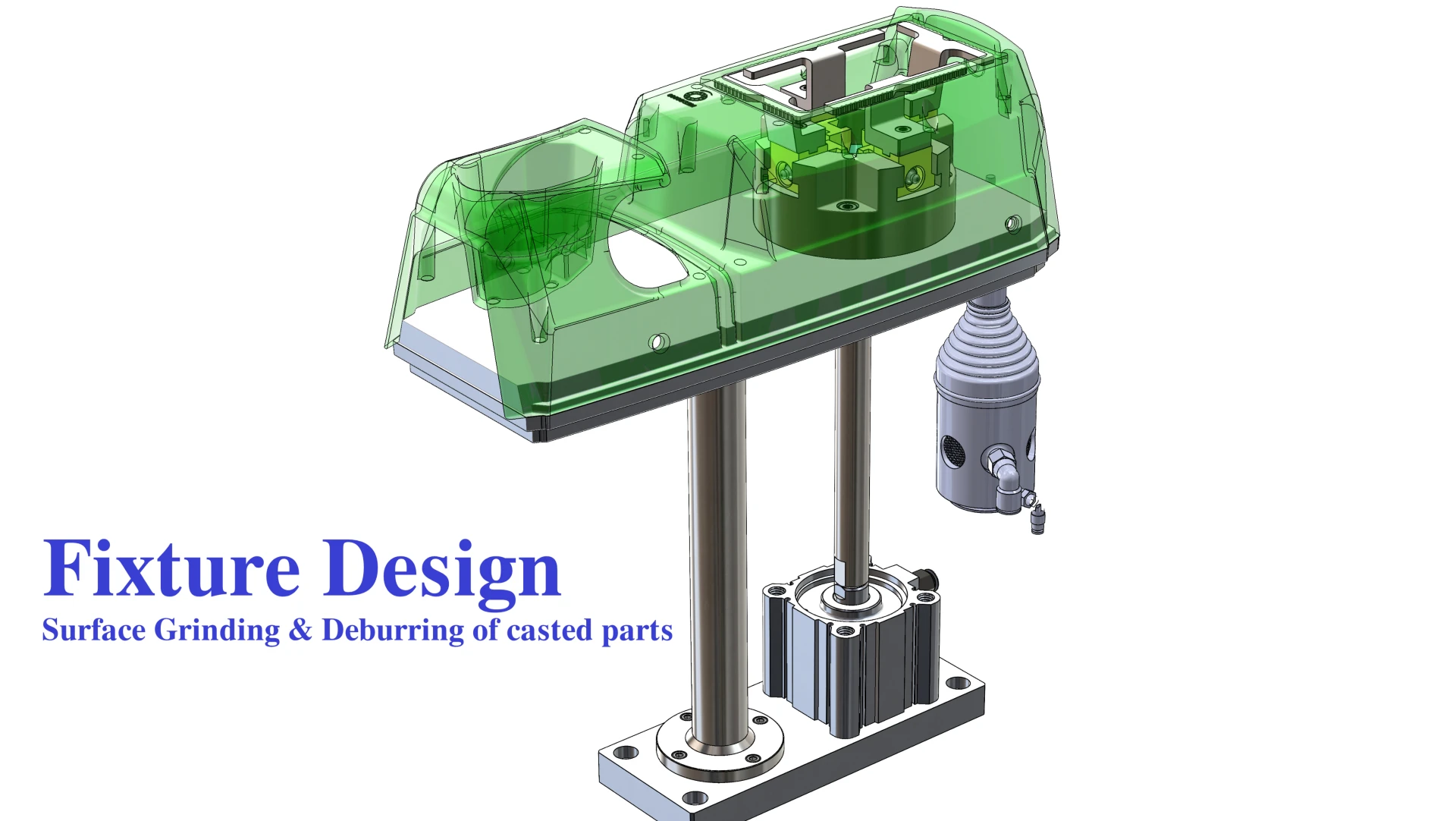

Machining Fixtures

- Precision fixturing for CNC, lathe, milling, and drilling operations to secure parts safely and achieve high accuracy and repeatability.

Inspection & Measuring Jigs

- Special jigs were developed to verify dimensional accuracy, check tolerances, and standardize inspection routines.

Assembly Jigs

- Solutions engineered to simplify assembly processes, reduce manual positioning errors, and streamline repetitive production tasks.

Workholding & Clamping Solutions

- Robust clamping systems are designed for stability, safety, and effective material handling during machining and fabrication.

Testing & Calibration Fixtures

- Fixtures built for performance testing, endurance evaluation, calibration, and product validation.

Our Design Approach

We focus on creating fixtures that are:

- Strong, safe, and rigid

- Simple to operate and maintain

- Cost-efficient to manufacture

- Optimized for accuracy and repeatability

- Compatible with your machines and workflows

Every design is analyzed for stress, force, tolerance, material compatibility, ergonomics, and manufacturability

Our Design Approach

We focus on creating fixtures that are:

- Strong, safe, and rigid

- Simple to operate and maintain

- Cost-efficient to manufacture

- Optimized for accuracy and repeatability

- Compatible with your machines and workflows

Every design is analyzed for stress, force, tolerance, material compatibility, ergonomics, and manufacturability.

Industries Served

Our fixture solutions support a wide range of sectors, including:

- Automotive

- Aerospace

- Manufacturing

- Fabrication & Welding

- Industrial Machinery

- Product Assembly

- Electronics

- Agricultural Equipment

Why Choose Us

- Expertise in SolidWorks, Inventor, Auto CAD, and simulation tools (Ansys)

- Strong understanding of machining and fabrication principles

- Proven engineering accuracy and reliability

- Clear communication and timely delivery

- Customized solutions for any scale of production

We work closely with clients to understand component geometry, production volume, tolerances, tooling requirements, and operational constraints. This ensures every fixture is engineered for practical use, not just theoretical intent.

Let Us Support Your Manufacturing Process

Whether you need a simple jig or a complex multi-stage fixture system, we are ready to assist. Our goal is to help you:

- Reduce production time

- Lower rework and scrap rates

- Improve product quality

- Increase consistency and repeatability

- Enhance safety and process efficiency