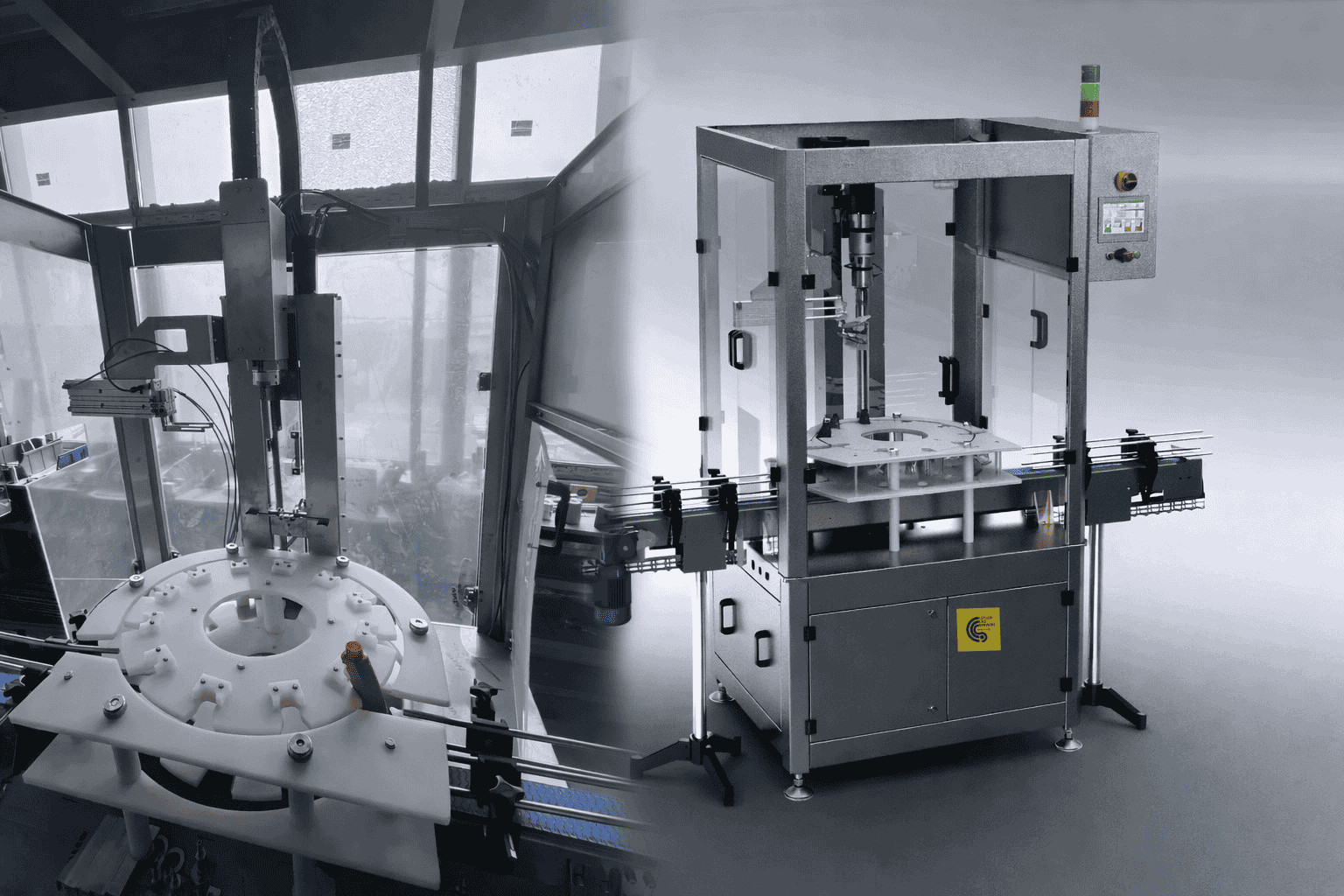

Special Purpose Machine (SPM) Design

We specialise in designing customised SPM (Special Purpose Machines) tailored for packing, filling, and material handling applications across various industries. Our solutions are developed to increase production efficiency, improve product handling accuracy, and minimize manual operations.

With strong expertise in CAD modelling, mechanical design, automation integration, and engineering analysis, we convert complex manufacturing challenges into reliable, user-friendly, and production-ready equipment.

Custom Solutions for Packing & Filling

We design high-efficiency machinery specifically engineered to automate your production line. Our focus is on reducing manual labor and increasing throughput without compromising accuracy.

- Filling Systems: Precision volumetric and gravimetric filling designs for liquids, powders, and granules.

- Primary & Secondary Packaging: Custom designs for bagging, wrapping, cartoning, and case packing.

- Sealing & Capping: High-speed mechanical designs for induction sealing, screw capping, and vacuum sealing.

Advanced Material Handling Equipment

Streamline your floor logistics with custom-engineered handling systems designed for durability and flow.

- Conveyor Systems: Design of belt, roller, slat, and modular conveyors tailored to your space and product type.

- Pick-and-Place Units: Pneumatic or servo-driven robotic arm end-effectors for high-speed sorting and palletizing.

- Automated Sorting & Buffering: Systems that manage product flow and reduce bottlenecks between processes.

- Lifts & Hoists: Custom heavy-duty lifting mechanisms for vertical material movement.

Technical Focus & Engineering Standards

Our SPM design process goes beyond 3D models; we focus on the mechanical integrity required for 24/7 industrial operations:

- Mechanism Synthesis: Designing linkages, cams, and gear trains for smooth, repeatable motion.

- Pneumatic & Hydraulic Integration: Full circuit design for actuators, cylinders, and manifolds.

- Safety & Compliance: Designs that incorporate machine guarding and ergonomic standards (ISO/OSHA).

- DFM (Design for Manufacturing): Ensuring that custom parts can be machined or fabricated cost-effectively.

Our Design Process for SPMs

- Requirement Analysis: We study your product cycle time and floor space constraints.

- Conceptualization: Developing 3D layouts to visualize the machine's footprint and movement.

- Detailed Design: Full 3D modeling of every bolt, bracket, and sensor mount.

- Manufacturing Drawings: Comprehensive 2D shop drawings with strict GD&T for precision assembly.

- BOM & Procurement: Providing a complete list of standard parts (motors, bearings, sensors) and custom-fabricated items.

Why Choose Our SPM Expertise?

- Modular Thinking: We design machines that are easy to maintain and upgrade.

- Precision Driven: We use tolerance stack-up analysis to ensure flawless assembly.

- Industry Experience: Deep knowledge of the sanitary requirements for food/pharma packing and the rugged needs of heavy material handling.