Advanced Simulation

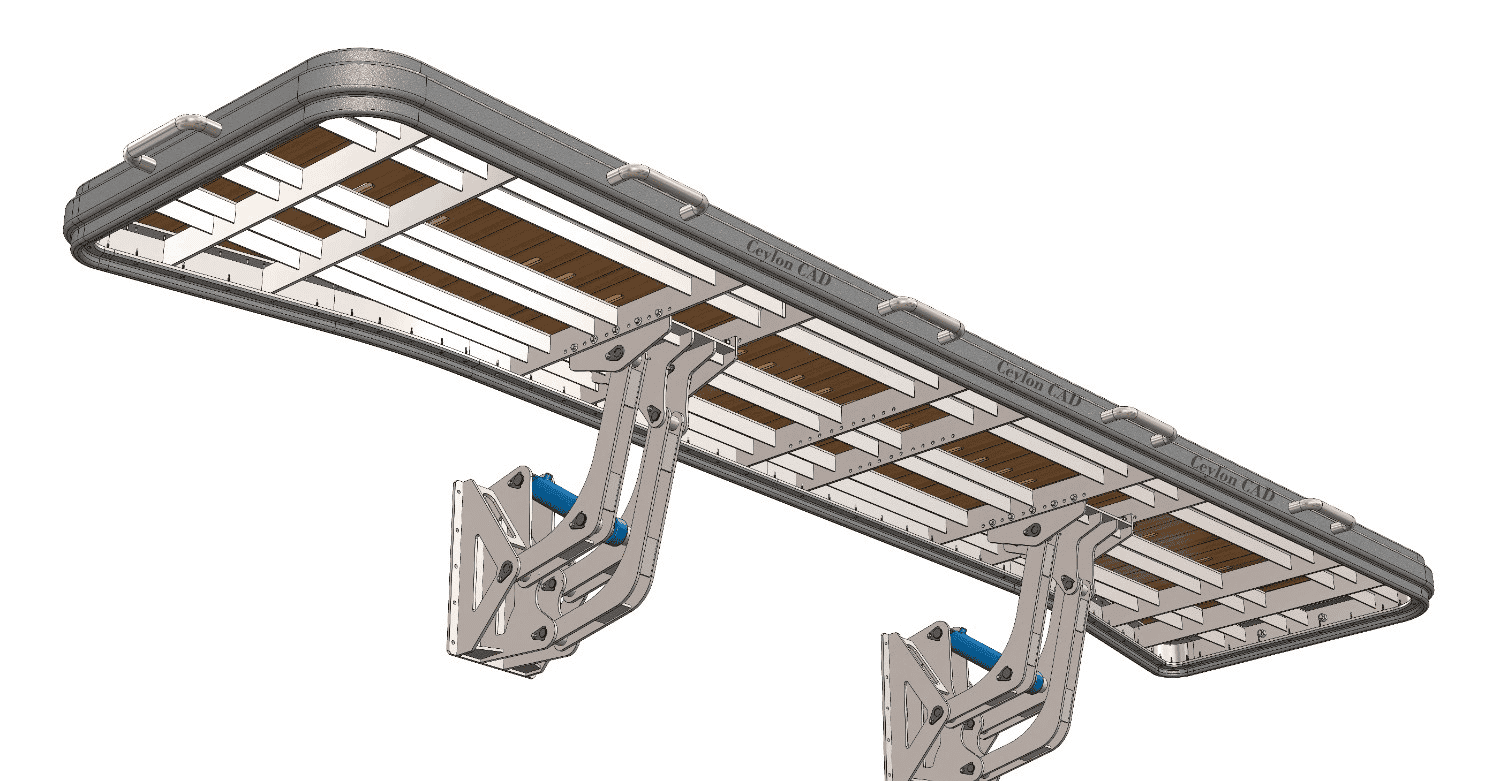

At Ceylon CAD, we specialize in advanced engineering simulations, including Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). These simulation tools are essential for enhancing product performance, ensuring reliability, and driving innovation across industries. We firmly believe that simulation is key to improving efficiency, reducing development risks, and staying competitive in today's fast-evolving market. By investing in simulation technologies, businesses can gain critical insights during the design phase, helping them avoid costly errors, reduce prototyping needs, and shorten time to market.

Our FEA and CFD services enable us to assess product behavior under various conditions, providing a deep understanding of structural integrity, thermal performance, and fluid flow dynamics. These analyses ensure that the final product is not only cost-effective and high-performing but also sustainable and ready for real-world application.

Advanced simulations rely on accurate numerical analysis, which allows for detailed testing in a virtual environment. This makes the process more efficient, minimizes the potential for error, and supports better design decisions early in the development cycle.

At Ceylon CAD, we are committed to delivering simulation-driven design solutions that meet your functional, performance, and business goals on time and with precision.

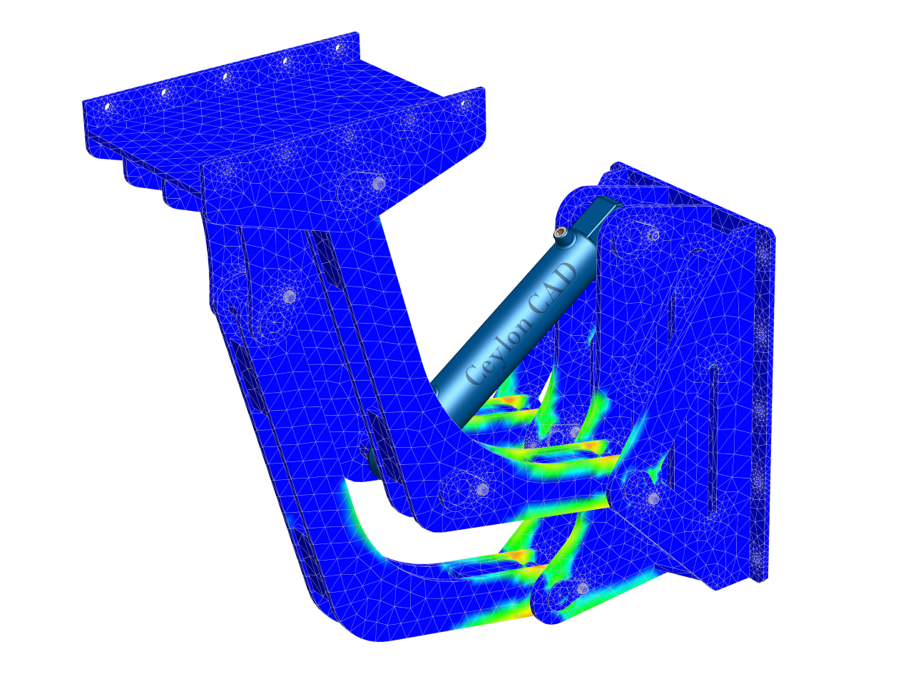

Finite Element Analysis (FEA)

Finite Element Analysis plays a critical role in our design and development process. It enables our engineers to evaluate multiple design alternatives by simulating and analyzing each option's performance, allowing us to identify the most effective and optimized solution for your product.

Through FEA, we are able to detect potential failure modes and areas where the design can be further improved. This not only enhances the overall quality and performance of the product but also significantly reduces development time and effort, ensuring a faster turnaround.

In cases where design customization is required, our team can efficiently modify specific dimensions and immediately assess the impact through simulation. This level of flexibility allows for quick iterations and informed decision-making, all prior to final production.

All designs are thoroughly tested using FEA before moving to the manufacturing stage, ensuring a final product that is both precise and reliable.

At Ceylon CAD, we utilize the latest simulation software and technologies to accurately analyze product efficiency and performance. This helps eliminate delays and ensures a smooth, streamlined path to product finalization.

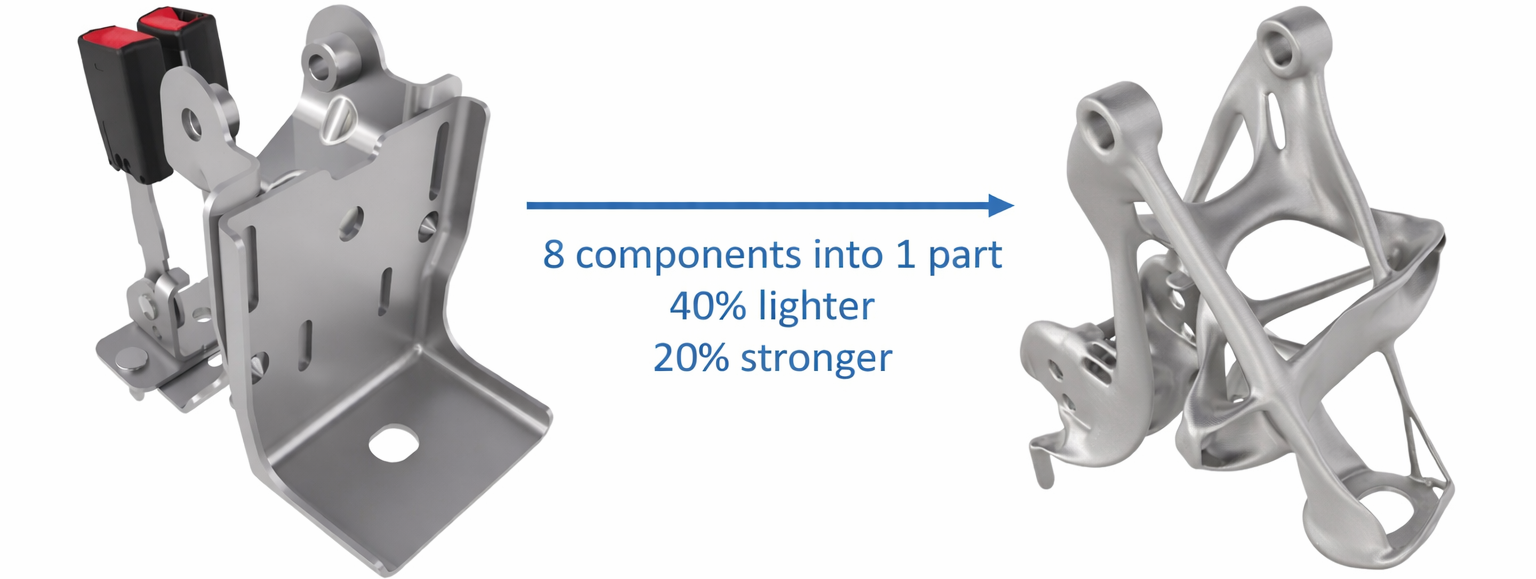

Design Optimization

Design optimization is essential to enhancing the performance, efficiency, and reliability of a product. At Ceylon CAD, our team of experts applies advanced engineering principles to refine and improve designs, taking into account various external factors such as load conditions, material behavior, manufacturing constraints, and environmental impacts.

An unsustainable or poorly optimized design may fail to meet functional and operational expectations. To mitigate this risk, we generate multiple design alternatives, evaluate them against key performance parameters, and identify the most effective solution.

All we require is a clear brief of your requirements, and our team will deliver a tailored, high-performance design that is both practical and innovative.